Machinery

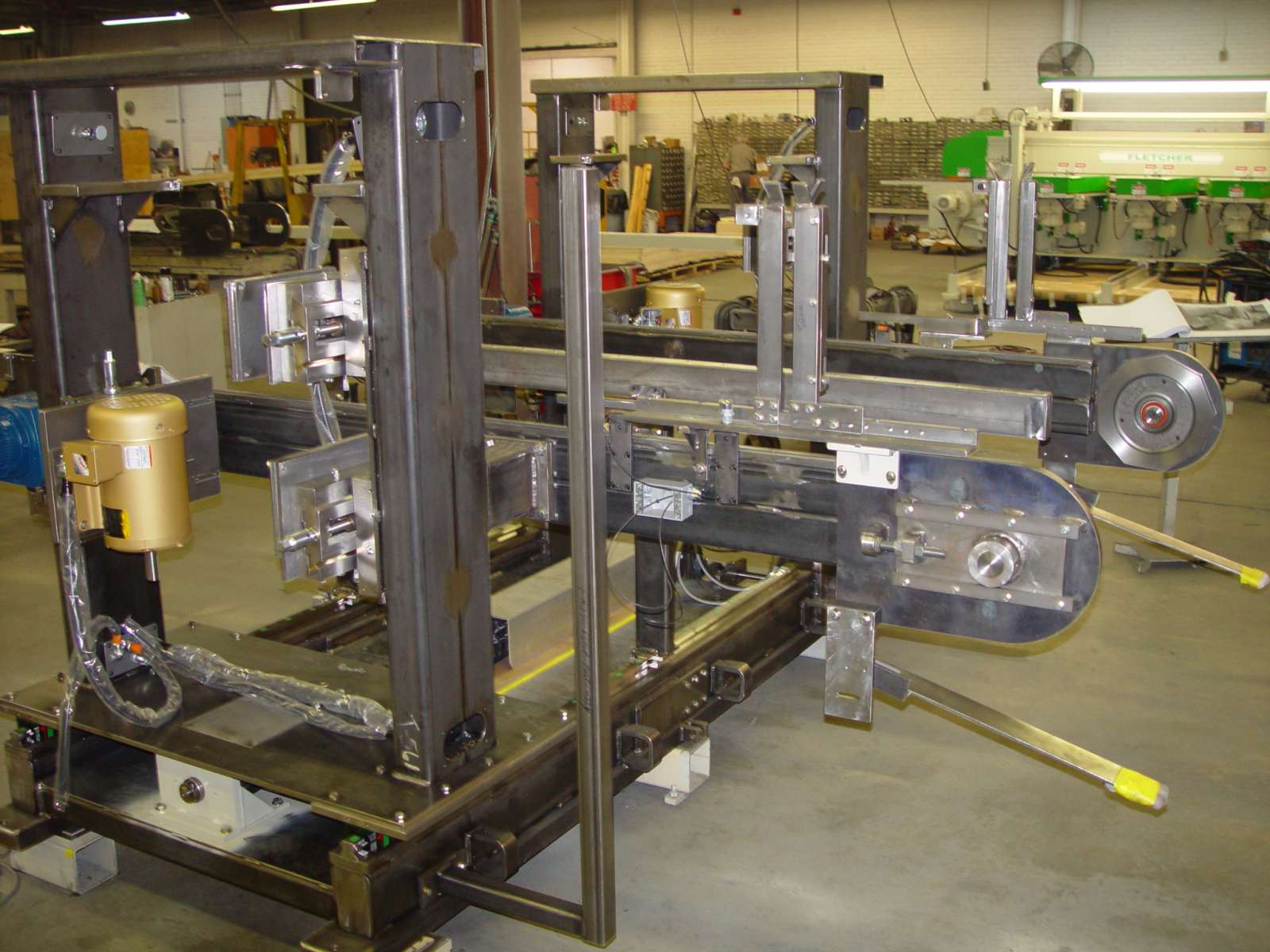

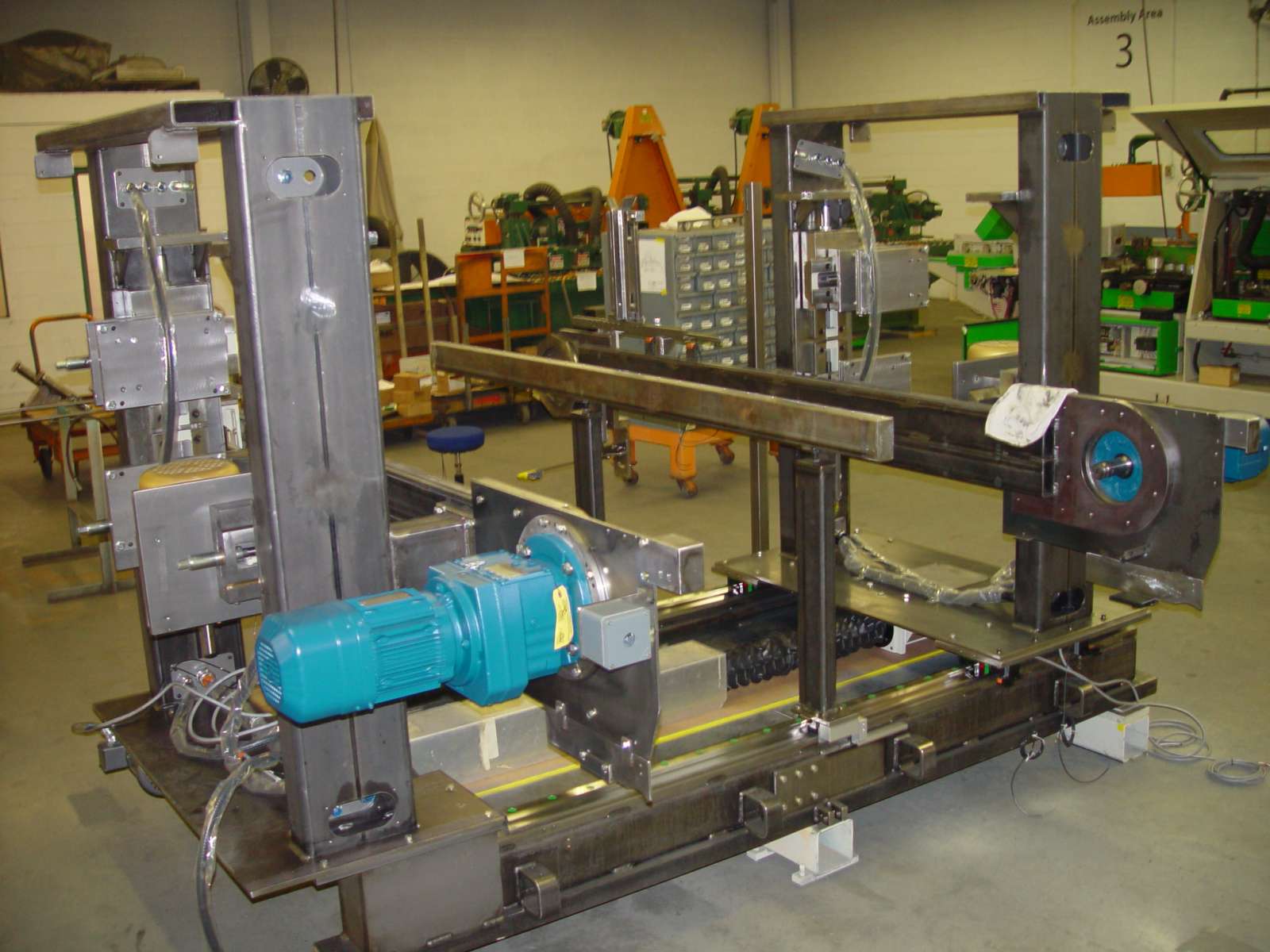

Multifunction machines that trim, shape, sand, foil, mould, drill, plane, route, edge band or press.

Multifunction machines that trim, shape, sand, foil, mould, drill, plane, route, edge band or press.

Machines Made Your Way.

On Our Highway.

Customization thrives in our neck of the woods.

Why do the “who’s who” of industry make their way to a little shop on East US Highway 64 in rural North Carolina to have their largest woodworking production machines designed and built … from the ground up?

Because we have big ears. That’s why.

Listening is our thing. It can be hard to understand our Davidson County drawl. So, we listen a lot. Eat barbeque. And talk even less.

The better we can understand our customers’ challenges. Large or small. We can help shape a solution unique to their situation. If you want cookie cutter. Or cheap. You’ve come to the wrong place.

We design and build machines to outlive the builder.

From our engineering department to the team of craftsmen who assemble the machines, we have a common purpose: build your machine to your specifications to meet the future needs of your company.

If you’re lucky enough to still own or have purchased a “used” Fletcher machine from the 60s, 70s, 80s or 90s, we’d be happy to make it like new. If you want, we’ll load it up with the latest electronics, pneumatics and computer controllers. And we’ll even do that for a competitor’s machine.

Built like we mean it. That’s Fletcher.

Bobby Miller, VP of Sales

(336) 362-3342

bmiller@fletcher-machine.com

Custom Machine Types

We design and build big machines that solve complex, high-production manufacturing problems. These machines execute a vast range of operations on a variety of materials including wood, PVC and composites.

Many of the machines fall under one of two platforms: single-end or double-end. There are several series of machines in each platform. Within these platform/series combinations, dozens of different machine variations can be designed and produced.

Single-end, Multifunction Platform

Double-end, Multifunction Platform

Contact Us

4305 E. US Highway 64, Lexington, NC 27292

Phone: (336) 249-6101 | Fax: (336) 249-6890 | Toll Free: (800) 438-1054